OUR PROCESSES

UNIFORJA focuses on the continuous improvement of its processes and the preservation of the environment, maintaining the following certifications:

- ISO 9001 (Quality Management System)

- IATF 16949 (Quality Management System for the automotive segment)

- IATF 16949 (Quality Management System for the automotive segment)

- ISO 14001 (Environmental Management System)

PRODUCTS

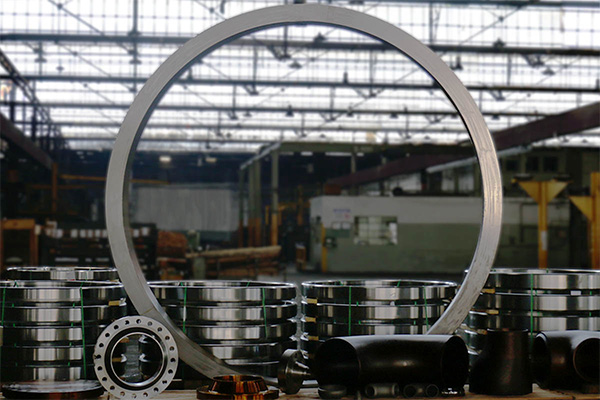

RINGS

We produce rings with and without profiles up to 4,600mm.

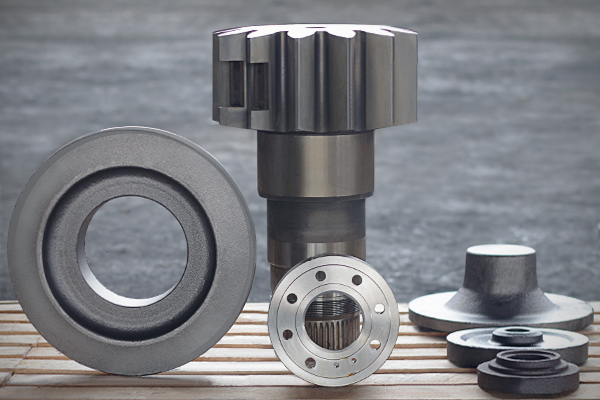

FLANGES

We manufacture flanges for various applications.

TUBULAR CONNECTIONS

We develop curves, reductions and tees according to the needs of the project.

CROWNS AND PINIONS

Crowns, pinions, flanges, coupling gloves and other forgings.

SERVICES

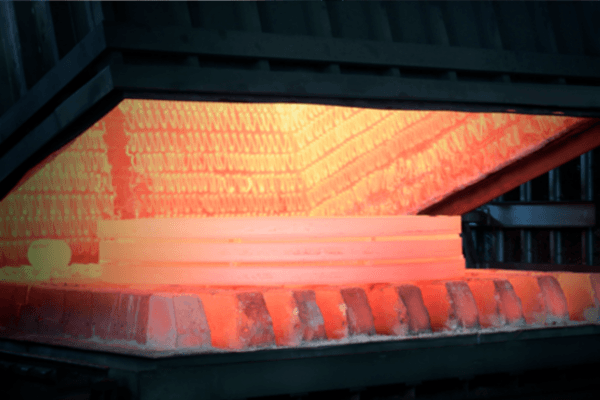

HEAT TREATMENT

Annealing, normalization, tempering, tempering, solubilization, stress relief, among other cycles.

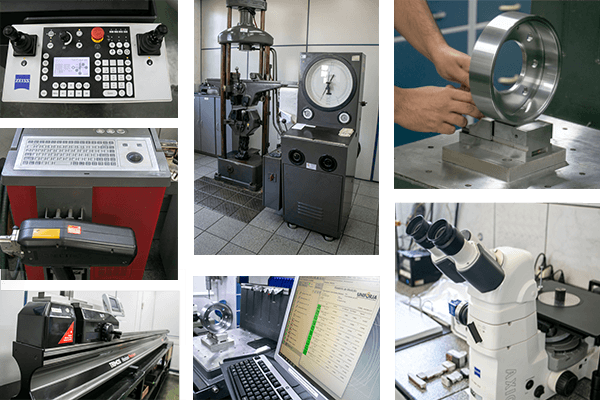

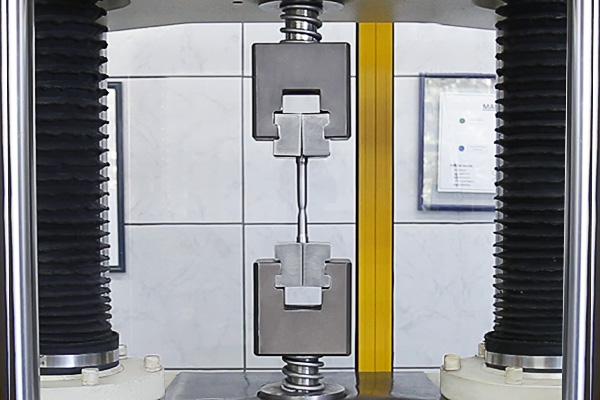

LABORATORY SERVICES

Mechanical and metallographic, with universal traction machines with a capacity of up to 60 ton .; impact machines (ASTM and DIN); optical emission spectrometer for chemical analysis of steel and equipment for hardness testing.

WE DEVELOP PROJECTS ACCORDING TO SPECIFIC DEMANDS

Our engineering team is composed of qualified professionals, aiming to guarantee the development of your project.

Request a quoteSERVED SEGMENTS

AERONAUTICAL

SUGAR/ALCOHOL

AUTOMOTIVE

CONSTRUCTION

WIND

NUCLEAR ENERGY

MACHINES

MINING

NAVAL

OIL/GAS

PETROCHEMICAL

LABORATORY SERVICES

25 YEARS OF A HISTORY MADE BY WORKERS! TOWARDS 26 YEARS OF SELF-MANAGEMENT.

ENVIRONMENT

The future of nature depends on what we do now, let’s take care of the environment today and forever!

ContactTECHNOLOGY

UNIFORJA has modern equipment that guarantees the application of the best production, control and testing techniques.